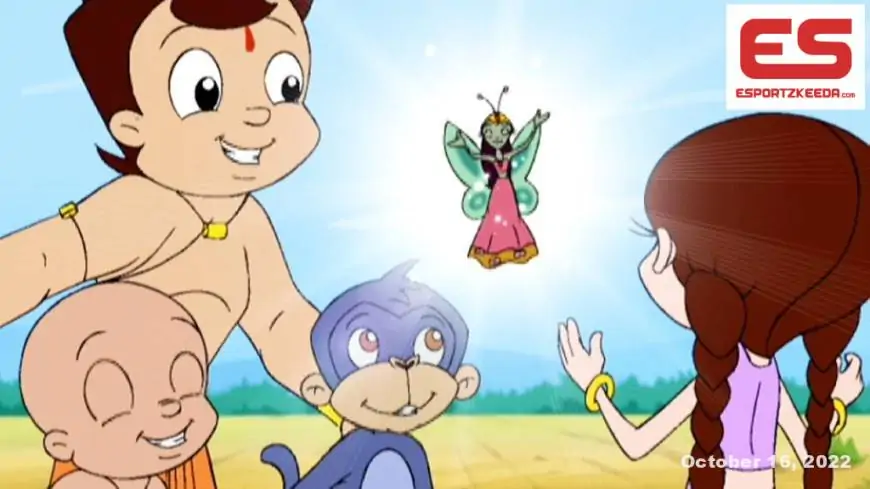

Now ramping up its manufacturing capability with rising Western distrust of China and India, the Made-in-China Barbie could must cope with Chhota Bheem. The massively fashionable character from a superhit animation TV series for youths, alongside along with his closest pal Chutki, has turn out to be a staple for desi toys – a desi barbie, for those who please.

Toys imported into India are dealing with some resistance. Within the growing success story of Atmanirbhar Bharat, India’s toy imports have fallen dramatically. And exports have picked up, which may be seen because the promise of the Make-in-India undertaking.

If we take Barbie as an emblem of Chinese language dominance in toy manufacturing and thus imported toys, and Chhota Bheem of India’s rising toy trade, then India’s toy story may be known as a battle of Barbie vs. Chhota Bheem. This may increasingly appear unattainable given the large hole in toy-making capability of China and India, however the battle has already begun. Prime Minister Narendra Modi himself has drawn the road for this struggle. In his Independence Day speech, he mentioned that even a five-year-old refuses to play with imported toys. The remark comes after years of encouragement to native toymakers.

The turning level in India’s toy story

The final three years have given a small however dramatic twist to the toy story of India. Based on authorities knowledge, imports of toys have fallen by 70 per cent within the final three years, whereas exports have grown by 61 per cent. Falling imports and a growth in home manufacturing have meant that a lot of Indian corporations are both solely manufacturing toys or solely importing elements and assembling toys in India. Indian producers have additionally began exploring new markets in Africa and the Center East.

The numbers present a flip in the direction of progress the place the scope is immense. Final yr, a report by KPMG and FICCI mentioned the largely unorganized Indian market was valued at simply $1 billion, of which 85% consisted of imported toys. Indians spent solely $3 per little one per yr on toys, in comparison with $300 per little one in North America and $34 in Asia. The report estimates the dimensions of the worldwide toy trade to be $95 billion in 2020.

India has made a really small begin in self-reliance, but when adopted, India can turn out to be a significant international participant in toy manufacturing,

How did this turn out to be potential?

Earlier than the dramatic rise in exports and decline in imports over the previous three years, there have been clear indicators of change. There was a decline of 12% in imports when it comes to CAGR between 2016-20. Modi turned a vocal supporter of the home toy trade. Urging the startups and entrepreneurs, he mentioned that the nation has the expertise and potential to turn out to be a toy manufacturing hub, particularly contemplating India’s modest share within the international toy market. “Construct groups for the toys,” he inspired.

Modi backed up his level with two concrete steps, which at the moment are largely attributed to the current progress spurt.

In February 2020, the federal government elevated the essential customized obligation on toys from 20 per cent to 60 per cent. This gave native producers a chance to develop. In January 2021, the federal government issued the BIS (Bureau of Indian Requirements) high quality certification for all toy producers and importers. High quality-control norms require all toys and supplies designed for play or supposed to be used by kids underneath the age of 14 to be licensed by BIS. Certification is required to be eligible on the market in India. Promoting with out certification can lead to fines and even felony prosecution. Greater than 800 producers, largely within the MSME sector, now have BIS certification.

Customs and high quality management have each restrained imports – low-cost in addition to prime quality – which didn't permit home manufacturing to flourish. The Covid lockdowns that depressed the sugar trade had been additionally an element.

A current HT report reported that over 100 toy makers in Delhi-NCR, which had been struggling to outlive until a number of years again, at the moment are on an growth drive. The brand new BIS rules have inspired many toy importers to fabricate their very own. One of many largest toy merchants of Delhi in Sadar Bazar finds it a lot simpler to turn out to be a producer simply two years again than an importer of toys due to the encouraging insurance policies of the federal government. Beforehand 95% of the toys in his store had been Chinese language; Now, 100% of them are made right here in his manufacturing unit.

What's the future?

Not glad with these two steps by the federal government to spice up home manufacturing, the toy trade needs a Nationwide Toy Coverage and Manufacturing Linked Incentive (PLI) scheme. It additionally needs a separate Export Promotion Council.

A nascent trade wants a hand-holding by the federal government. Equally, China and Vietnam have grown in manufacturing. Toymakers need the federal government to assist create a producing ecosystem that may appeal to worldwide corporations from different Asian nations. It'll take lengthy and sustained efforts by each the federal government and trade. A toy maker instructed HT that the federal government ought to carry engineering establishments and MSMEs collectively to develop particular objective machines. “We should be self-sufficient within the manufacturing of digital chips and motors for toys, that are imported from China,” he mentioned.

The KPMG-FICCI report says that it's comparatively simple for India to turn out to be a lovely different to China for labour-intensive merchandise like gentle toys on account of India’s cost-competitiveness. This phase of the toy market is the low hanging fruit for India.

Whereas toys primarily based on mythology and faith could also be fashionable inside the nation, if India needs to turn out to be a giant toy exporter, it has to give attention to sensible toys. There's already a motion for this.

A Mint report highlights how the Indian producer has been main the best way in designing and producing STEM (science, expertise, engineering and math) toys primarily based on run-of-the-mill board video games, dolls and remote-controlled Shifting away from automobiles. A number of younger Indian corporations at the moment are altering the marketplace for dad and mom desirous to see their youngsters transcend conventional toys.

It added that a number of Indian STEM startups- Butterfly Edufields, Skillmatics, Jackin thebox and Playsifu, are gaining floor in a global market dominated by massive names like Lego, Mattel and Hasbro to call a number of.

A provider of elements for the aerospace trade and now a contract producer for main international toy manufacturers, Aikus has arrange an enormous manufacturing cluster in Koppal, Karnataka. It hopes to drive main toy corporations away from China and different nations.

India’s largest impediment

Given its edge in innovation and design, Ax might be able to overcome this to some extent, however for the complete Indian trade to compete with China appears a tall order within the close to future. About 90% of India’s toy trade is within the unorganized sector, and most have little entry to high quality uncooked supplies or the newest expertise.

That is the place the Barbie-Chhota Bheem struggle appears to be a wierd mismatch.

India’s largest constraint as in comparison with China is the dearth of a home manufacturing ecosystem that's cost-effective, environment friendly and modern. The KPMG-FICCI report states that India lacks the required home provide chain for high quality manufacturing on a big scale. A lot of the uncooked supplies and machines for manufacturing toys are sourced from China and different Asian nations. Uncooked supplies reminiscent of polymers, paper, boards and non-toxic paints are sourced largely from China, Hong Kong, Sri Lanka and Malaysia. Plastic- and rubber-molding machines are sourced largely from China and South Korea. Digital elements reminiscent of circuit boards, capacitors, motors, PCBs and LEDs are additionally largely imported from China, Taiwan and South Korea.

Even every kind of material, which is 30% uncooked materials of plush toys, are usually not obtainable domestically and should be imported from China. Each hair fiber and hair-routing machines for doll manufacturing are once more largely imported from China and South Korea. The Indian trade additionally lacks design abilities and engineering, particularly for toy manufacturing, reminiscent of 3D product prototyping. India additionally wants extra licensed testing amenities.

No manufacturing nation can supply all of the uncooked supplies and intermediates and add all the worth domestically, however within the case of toy manufacturing in India, the shortfall is extreme.

Nevertheless, the Acous Manufacturing Cluster provides a glimpse of a potential, if distant, future as it's now sure that China is not going to be the one choice for Western corporations to fabricate in Asia. Extra prime quality producers like Ekas will make the most of this.

Many massive toy corporations are shifting away from China. Lego and Hasbro are diversifying different locations. Apparently, Mattel, the creators of Barbie, does the identical. It's increasing its plant in Mexico, which guarantees extra dependable provide to the US market on account of its shut proximity to the US. Mattel’s new plant is its largest, bigger than different manufacturing facilities in China, Vietnam and Malaysia.

The Kovid lockdown slowed down the toymakers of China. As soon as China is absolutely again in enterprise, it is going to be a tricky take a look at for Indian producers. They need increased customs duties to proceed to guard them.

If Chhota Bheem has to struggle Barbie, he'll want greater than a chutki from his facet. He must be tech savvy and assume past conventional toys. It’s an extended, laborious struggle. For now, he's prepared with customs and high quality management.

Denial of obligation! upresults.org is an computerized aggregator internationally media. The entire content material materials supplies provides is also discovered free on Web. We now have now merely organized it in a single platform for tutorial perform solely. In each content material materials supplies provides, the hyperlink to the primary current is specified. All emblems belong to their rightful homeowners, all provides to their authors. In case you’re the proprietor of the content material materials supplies provides and don’t want us to publish your provides on our website on-line, please contact us by e mail – upresultsnews@gmail.com. The content material materials supplies provides is also deleted inside 24 hours.

Disclaimer: We at www.esportzkeeda.com request you to take a look at motion photographs on our readers solely with cinemas and IPL, Sports, Hotstar and any official digital streaming companies. Don’t use the pyreated web site to amass or view online.

Publish date: 2022-10-15 13:16:19

Get All Fantasy Cricket Ideas and Information - Click Here

#Battle #Barbie #Chhota #Bheem #hindi #well being